Products

FPCB

The advantages of flex boards include compact product size, lightweight, flexibility, the ability to conform to spatial constraints and three-dimensional wiring, increased wiring density in systems, and reduced wiring errors. Flex boards find extensive applications in a wide range of fields such as computers and peripherals, communication products, consumer electronics, automotive, and military industries.

-

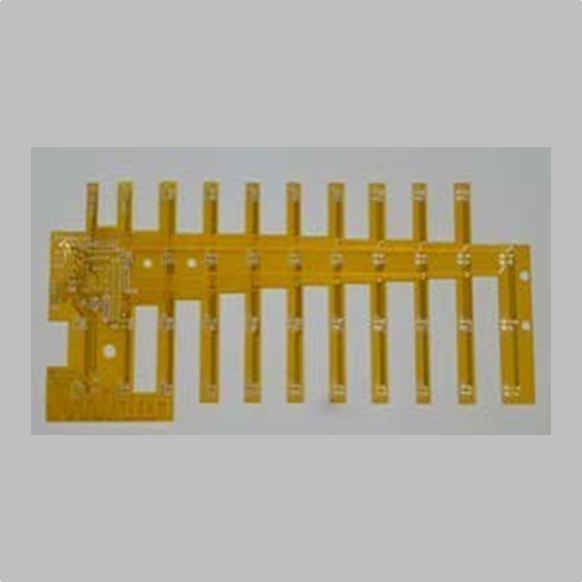

Single Layer FPC

Typically constructed by combining a single-sided substrate with a solder mask layer, flexible printed circuit boards (FPCBs) are known for their extremely lightweight, thin, and highly flexible characteristics. They are primarily used in consumer electronics, displays, communications, and other related fields.

Double Layer FPC

Using double-sided substrates with copper plating achieved through drilling enables top and bottom layer conductivity, providing lightweight, flexible characteristics suitable for three-dimensional assembly. This makes it a foundational component in numerous electronic products, widely applied in consumer electronics, smart terminals, mobile wearables, high-frequency high-speed applications, industrial control, automotive, medical devices, and other fields.

Multi-Layer FPC

Constructed from multiple single-sided or double-sided substrates and pure adhesives using various stacking processes, each layer of these flexible printed circuit boards (FPCBs) contains circuit patterns, enabling inter-layer conductivity. They significantly enhance design flexibility within limited space dimensions and offer a degree of flexibility for ease of assembly. Currently, they are predominantly used in consumer electronics, high-frequency communication, and other related fields.

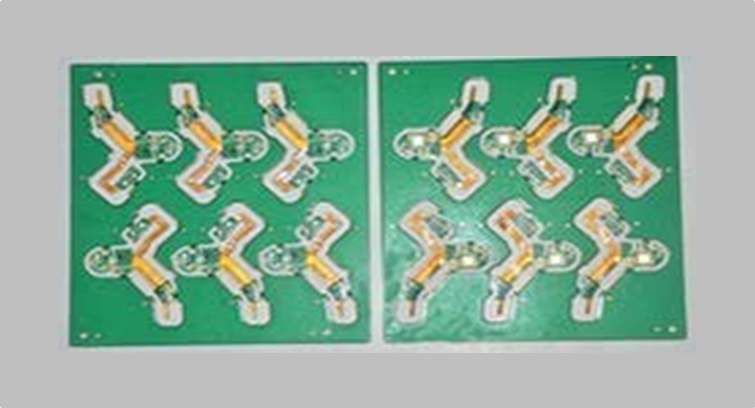

Flex-Rigid PCB

Rigid-Flex PCBs are products formed through the layering of local materials using processes such as pressing and opening, simultaneously possessing characteristics of both FPC and PCB. This design not only enhances design flexibility within limited spatial dimensions but also meets the complex requirements of soldering and 3D assembly applications. With technological advancements, high-end products like Arbitrary Layer Interconnect (HDI) are gradually achieving mass production. Currently, rigid-flex boards are widely used in high-end consumer electronics, smart terminals, displays, aerospace, defense, and other industries.

High-Density Interconnect Multi-Layer FPC

In response to the trend of multi-layer applications, NESSIE provides flexible boards that have transitioned from traditional single-layer and double-layer connectivity to HDI (High Density Interconnect). This evolution through HDI addresses the precision requirements for blind via stacking. Micro vias and buried vias are typically achieved through layer stacking, categorized as single-layer HDI, double-layer HDI, triple-layer HDI, and Anylayer HDI for various layer counts.

-

For further details, please contact us.

Contact Person: Diane Yeh

TEL: 02-86659877 #302

Mobile: 0988425153

Email: diane.yeh@nessie.com.tw

Assistant: Ms. Chu, 02-86659877 #205 -